Compatibilizer impact on the mechanical properties of doum fiber reinforced polyestercomposite

Keywords:

Doum fibers, Compatibilizer, Maleic anhydride, Unsaturated polyesterAbstract

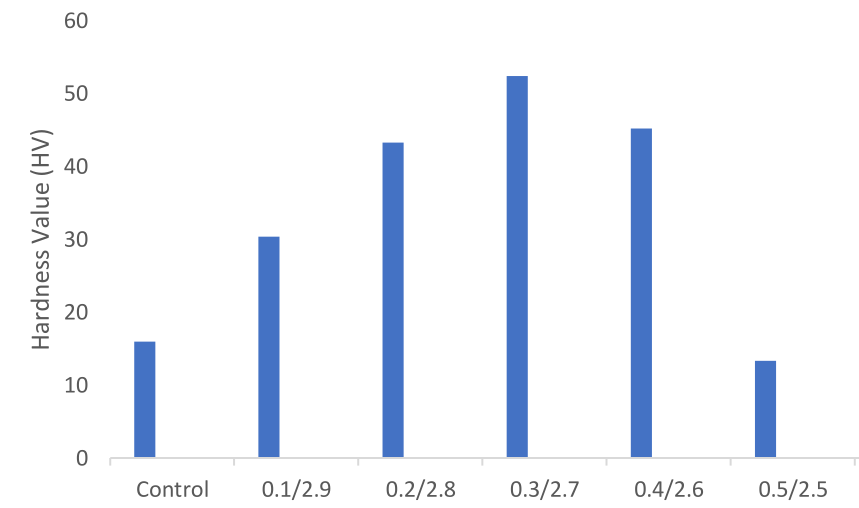

Natural fibers such as doum, jute, and hemp are emerging as alternatives to glass fibers for reinforcing polymer composites. However, the hydrophilic nature of natural fibers often leads to poor adhesion with hydrophobic polymer matrices. This results in inferior mechanical properties of the composites. This study aimed to investigate the effect of incorporating maleic anhydride (MA) as a compatibilizer on the hardness and tensile property of doum fiber-reinforced unsaturated polyester (UP) composites. MA as a compatibilizer has been used in a few studies and the good efficiency of MA was shown by the good interaction of maleic anhydride non-polar chain with the polymer matrix [20]. Dom fibers were manually extracted and treated with a 5% NaOH solution. The UP resin was reinforced with 0.3-2.7 wt% untreated doum fibers and 0.3-2.7 wt% MA was added as the compatibilizer. The components were mixed thoroughly and cured by hand layup technique. Hardness was evaluated using a Vickers hardness tester. tensile tests were performed on an electronic universal testing machine to determine the tensile strength, elastic modulus, and elongation at break. Three (3) samples were tested for each composition and the results were averaged. Incorporating MA led to a significant increase of about 225 and 106% in hardness and tensile strength respectively compared to the control. Accordingly, the addition of MA improved the interfacial adhesion between the hydrophilic doum fibers and hydrophobic UP resin matrix, hence, improved the hardness and tensile property of the composites.

Published

How to Cite

Issue

Section

Copyright (c) 2025 R. M. Dodo, I. I. Abubakar, Z. Musa, K. A. Bello, M. N. Bala, S. K. Muhammad (Author)

This work is licensed under a Creative Commons Attribution 4.0 International License.