Baobab shell powder as a bio-filler in HDPE composites: mechanical, and physical properties

Authors

-

Daniel S. Sudi

Department of Metallurgical and Materials Engineering, Air Force Institute of Technology, Kaduna, Nigeria

-

Haruna P. Wante

Plasma Technology Research Centre, Department of Physics, Faculty of Science, Universiti Malaya, Kuala Lumpur 50603, Malaysia

-

Ndubuisi Mbada

Department of Metallurgical and Materials Engineering, Air Force Institute of Technology, Kaduna, Nigeria

-

Isah Baba

Department of Metallurgical and Materials Engineering, Air Force Institute of Technology, Kaduna, Nigeria

-

Bamidele Boluwatife

Department of Metallurgical and Materials Engineering, Air Force Institute of Technology, Kaduna, Nigeria

-

Solomon Adeleke

Department of Metallurgical and Materials Engineering, Air Force Institute of Technology, Kaduna, Nigeria

Keywords:

Baobab shell powder (BSP), Lignocellulosic materials, High-density polyethylene (HDPE), Bio-fillerAbstract

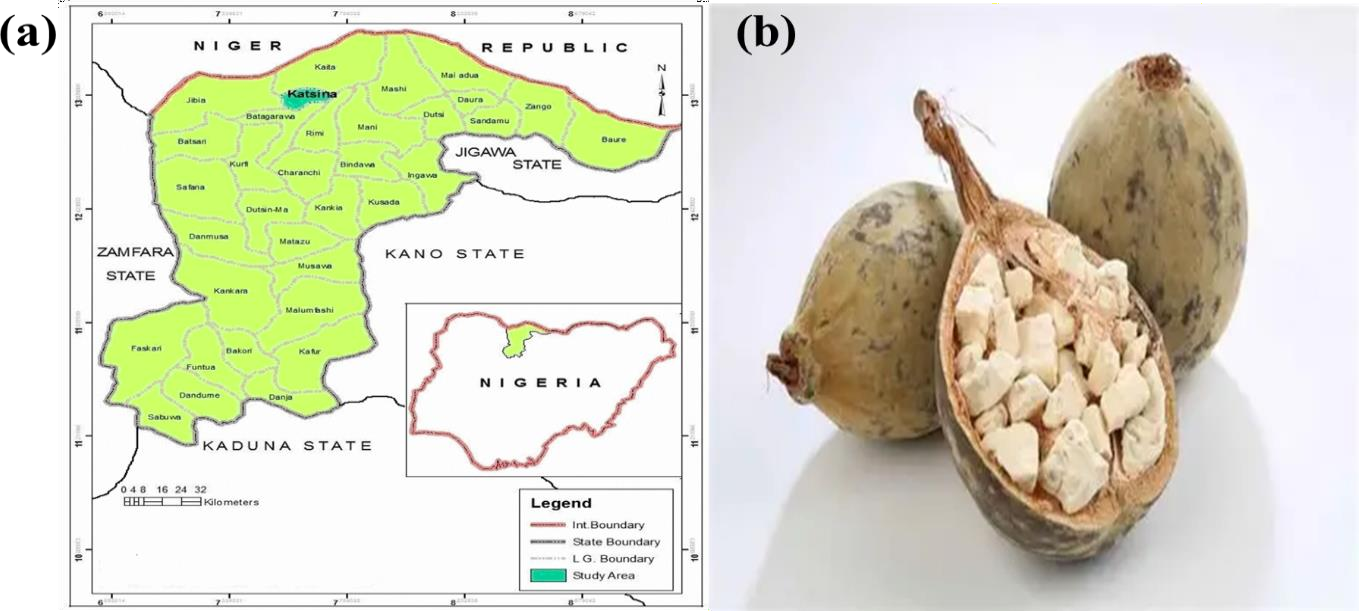

This study develops and characterizes high-density polyethylene (HDPE) composites reinforced with 0–20 wt% baobab shell powder (BSP) as a sustainable bio-filler. Composites were fabricated via compression molding and assessed for mechanical, physical, and chemical properties. XRF analysis revealed high metal oxide content in BSP—K2O (29.32%), MgO (16.27%), CaO (12.42%), Al2O3 (12.12%), and SiO2 (11.73%)—indicating multifunctional potential. FTIR confirmed lignocellulosic functional groups (O–H, C–H, C=O, C–O). Tensile strength peaked at 10.996 N/mm2 (20 wt%, +6.14% vs. neat HDPE); yield strength peaked at 26.35 N/mm2 (15 wt%), suggesting improved matrix interaction. Flexural strength dropped to 2.24 N/mm2 at 10 wt% but stabilized thereafter; elongation at break fell from 37.74% to 7.87%, indicating increased rigidity. Impact energy dropped from 4.0 J to 1.63 J, while hardness and density rose from 11.36 to 28.66 N/m2 and 0.87 to 0.93 g/cm3, respectively. Water absorption remained low until day 6, then rose sharply to ~20% (20 wt%) by day 8 due to interfacial degradation. Composites with ≤10 wt% BSP showed better moisture resistance. The results demonstrated that BSP enhances stiffness, hardness, and tensile strength but reduces ductility and impact resistance, making it suitable for non-structural applications in automotive, packaging, and sustainable construction.

[1] R. G. Mandala, D. Hegde, V. R. Kodali & V. R. Kode, “From waste to strength: Unveiling the mechanical properties of peanut-shell-based polymer composites”, Journal of Composites Science 7 (2023) 307. https://doi.org/10.3390/jcs7080307. DOI: https://doi.org/10.3390/jcs7080307

[2] H. T. N. Kuan, M. Y. Tan, Y. Shen & M. Y. Yahya, “Mechanical properties of particulate organic natural filler-reinforced polymer composite: A review”, Composites and Advanced Materials 30 (2021) 26349833211007502. https://doi.org/10.1177/26349833211007502. DOI: https://doi.org/10.1177/26349833211007502

[3] T. K. Das, P. Ghosh & N. C. Das, “Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review”, Advanced Composites and Hybrid Materials 2 (2019) 214. https://doi.org/10.1007/s42114-018-0072-z. DOI: https://doi.org/10.1007/s42114-018-0072-z

[4] J. Oboh, J. Okafor, A. Kovo & A. Abdulrahman, “Investigation of eco-friendly cellulosic nanoparticles potential as reinforcement agent in the production of natural rubber composites”, Nigerian Journal of Technology 36 (2017) 1078. https://doi.org/10.4314/njt.v36i4.13. DOI: https://doi.org/10.4314/njt.v36i4.13

[5] M. Y. Khalid, A. Al Rashid, Z. U. Arif, W. Ahmed, H. Arshad & A. A. Zaidi, “Natural fiber reinforced composites: Sustainable materials for emerging applications”, Results in Engineering 11 (2021) 100263. https://doi.org/10.1016/j.rineng.2021.100263. DOI: https://doi.org/10.1016/j.rineng.2021.100263

[6] S. Araby, B. Philips, Q. Meng, J. Ma, T. Laoui & C. H. Wang, “Recent advances in carbon-based nanomaterials for flame retardant polymers and composites”, Composites Part B: Engineering 212 (2021) 108675. https://doi.org/10.1016/j.compositesb.2021.108675. DOI: https://doi.org/10.1016/j.compositesb.2021.108675

[7] M. Harussani, S. Sapuan, G. Nadeem, T. Rafin & W. Kirubaanand, “Recent applications of carbon-based composites in defence industry: A review”, Defence Technology 18 (2022) 1281. https://doi.org/10.1016/j.dt.2022.03.006. DOI: https://doi.org/10.1016/j.dt.2022.03.006

[8] A. Soni, P. K. Das, S. K. Gupta, A. Saha, S. Rajendran, H. Kamyab & M. Yusuf, “An overview of recent trends and future prospects of sustainable natural fiber-reinforced polymeric composites for tribological applications”, Industrial Crops and Products 222 (2024) 119501. https://doi.org/10.1016/j.indcrop.2024.119501. DOI: https://doi.org/10.1016/j.indcrop.2024.119501

[9] M. Sidibe & J. T. Williams, Baobab, Adansonia Digitata L, Crops for the Future Series, International Centre for Underutilised Crops, 2002. https://books.google.com.ng/books?id=zskefIIlc1IC.

[10] A. H. Birniwa, S. S. Abdullahi, M. Ali, R. E. A. Mohammad, A. H. Jagaba, M. Amran, S. Avudaiappan, N. Maureira-Carsalade & E. I. S. Flores, “Recent trends in treatment and fabrication of plant-based fiber-reinforced epoxy composite: a review”, Journal of Composites Science 7 (2023) 120. https://doi.org/10.3390/jcs7030120. DOI: https://doi.org/10.3390/jcs7030120

[11] J. Sundarababu, S. S. Anandan & P. Griskevicius, “Evaluation of mechanical properties of biodegradable coconut shell/rice husk powder polymer composites for light weight applications”, Materials Today: Proceedings 39 (2021) 1241. https://doi.org/10.1016/j.matpr.2020.04.095. DOI: https://doi.org/10.1016/j.matpr.2020.04.095

[12] M. A. Suhot, M. Z. Hassan, S. A. A. Aziz & M. Y. Md Daud, “Recent progress of rice husk reinforced polymer composites: A review”, Polymers 13 (2021) 2391. https://doi.org/10.3390/polym13152391. DOI: https://doi.org/10.3390/polym13152391

[13] R. Premkumar, R. R. Babu, V. S. Jatti & V. SN, “Coconut fiber reinforced with wood charcoal, egg shell filler powder with polyester resin composite for automotive applications”, Next Research 2 (2025) 100414.https://doi.org/10.1016/j.nexres.2025.100414. DOI: https://doi.org/10.1016/j.nexres.2025.100414

[14] S. Radhakrishnan, J. S. Krishna, S. P. Dwivedi, S. Gupta, P. Gupta & V. Chaudhary, “Experimental investigation of mechanical and physical properties of coconut shell and eggshell filler-based bio-fiber reinforced epoxy hybrid composites”, Biomass Conversion and Biorefinery 15 (2025) 3201. https://doi.org/10.1007/s13399-023-05037-4. DOI: https://doi.org/10.1007/s13399-023-05037-4

[15] X. Li, L. G. Tabil & S. Panigrahi, “Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review”, Journal of Polymers and the Environment 15 (2007) 25. https://doi.org/10.1007/s10924-006-0042-3. DOI: https://doi.org/10.1007/s10924-006-0042-3

[16] M. M. Ruma, A. M. A. Badr, S. Khater & A. M. M. El-tantawi, “Assessment of some physicochemical parameters levels in sachet drinking water and its effects on human health in Katsina Urban Area, Nigeria”, Science World Journal 9 (2014) 19. https://doi.org/10.4314/swj.v9i1.3.

[17] B. O. Samuel, “Manufacturing parameters optimization and modeling of PxGyEz hybrid composite for high flexural strength using Taguchi robust experimental design technique and general regression analysis”, Research Square (2021). Preprint. [Online]. https://doi.org/10.21203/rs.3.rs-831643/v1. DOI: https://doi.org/10.21203/rs.3.rs-831643/v1

[18] A. Balaji, S. Kannan, R. Purushothaman, S. Mohanakannan, A. H. Maideen, J. Swaminathan, B. Karthikeyan & P. Premkumar, “Banana fiber and particle-reinforced epoxy biocomposites: mechanical, water absorption, and thermal properties investigation”, Biomass Conversion and Biorefinery 14 (2024) 7835. https://doi.org/10.1007/s13399-022-02829-y. DOI: https://doi.org/10.1007/s13399-022-02829-y

[19] R. Kenneth, K. M. Kalu, N. A. Haruna, E. K. Chinedu, I. Atiku & M. Emmanuel, “Baobab (Adansonia digitata) pulp and mango seeds as new adsorbents for the removal of Pb (II) ions from aqueous solutions”, Asian Journal of Chemical Science 13 (2023) 13. https://doi.org/10.9734/ajocs/2023/v13i6277. DOI: https://doi.org/10.9734/ajocs/2023/v13i6260

[20] F. Kapile, Influence of rice husk derived nano-silica on performance, emissions, and combustion characteristics of diesel engine fueled with baobab biodiesel, Ph.D. dissertation, Nelson Mandela African Institution of Science and Technology, NM-AIST, Tanzania, 2024. https://dspace.nm-aist.ac.tz/bitstream/handle/20.500.12479/2733/PhD_SESE_%20Kapile_Fredrick_2024.pdf?sequence=1.

[21] H. Mao, F. Wang, X. Zhu, X. Chen, W. Li & W. Zhang, “Design of a BaO–Al2O3–SiO2–B2O3 glass-ceramic for microwave LTCC substrate material based on glass-ceramic+ ceramic composite”, Journal of Materials Science: Materials in Electronics 33 (2022) 24834. https://doi.org/10.1007/s10854-022-09194-6. DOI: https://doi.org/10.1007/s10854-022-09194-6

[22] X. Yan, X. Wang, S. Wang, S. Zhang, X. Zhang, Q. Wang & Q. Wang, “Influence of Al2O3/SiO2 and BaO/Al2O3 ratios on rheological and crystallization behavior of CaO–BaO–Al2O3-based mold slags”, ISIJ International 62 (2022) 1116. https://doi.org/10.2355/isijinternational.ISIJINT-2021-565. DOI: https://doi.org/10.2355/isijinternational.ISIJINT-2021-565

[23] C. Silva, F. Bobillier, D. Canales, F. Antonella Sepúlveda, A. Cament, N. Amigo, L. M. Rivas, M. T. Ulloa, P. Reyes & J. A. Ortiz, “Mechanical and antimicrobial polyethylene composites with CaO nanoparticles”, Polymers 12 (2020) 2132. https://doi.org/10.3390/polym12092132. DOI: https://doi.org/10.3390/polym12092132

[24] A. Akbari, M. Amini, A. Tarassoli, B. Eftekhari-Sis, N. Ghasemian & E. Jabbari, “Transition metal oxide nanoparticles as efficient catalysts in oxidation reactions”, Nano-Structures & Nano-Objects 14 (2018) 19. https://doi.org/10.1016/j.nanoso.2018.01.006. DOI: https://doi.org/10.1016/j.nanoso.2018.01.006

[25] R. van de Krol, Y. Liang & J. Schoonman, “Solar hydrogen production with nanostructured metal oxides”, Journal of Materials Chemistry 18 (2008) 2311. https://doi.org/10.1039/B718969A. DOI: https://doi.org/10.1039/b718969a

[26] W. Lamai, P. Aunbamrung & A. Wongkaew, “Characteristic and catalytic activity of CuO supported over Fe2O3 catalyst for CO removal”, International Conference Burapha University, Thailand, 2014. https://www.researchgate.net/publication/295907081_Characteristic_and_Catalytic_activity_of_CuO_supported_over_Fe2O3_catalyst_for_CO_removal/figures?lo=1.

[27] H. Ma, Q. Zhuo & B. Wang, “Characteristics of CuO-MoO3-P2O5 catalyst and its catalytic wet oxidation (CWO) of dye wastewater under extremely mild conditions”, Environmental Science & Technology 41 (2007) 7491. https://doi.org/10.1021/es071057p. DOI: https://doi.org/10.1021/es071057p

[28] W. Han, Q. Shi & R. Hu, “Advances in electrochemical energy devices constructed with tungsten oxide-based nanomaterials”, Nanomaterials 11 (2021) 692. https://doi.org/10.3390/nano11030692. DOI: https://doi.org/10.3390/nano11030692

[29] S. G. Krishnan, A. Arulraj, M. Khalid, M. Reddy & R. Jose, “Energy storage in metal cobaltite electrodes: Opportunities & challenges in magnesium cobalt oxide”, Renewable and Sustainable Energy Reviews 141 (2021) 110798. https://doi.org/10.1016/j.rser.2021.110798. DOI: https://doi.org/10.1016/j.rser.2021.110798

[30] S. Chayoukhi, B. Gassoumi, H. Dhifelaoui, A. Boukhachem & M. Amlouk, “Nanomechanical behavior, adhesion and wear resistance of tin oxide coatings for biomedical applications”, Materialwissenschaft undWerkstofftechnik 55 (2024) 427. https://doi.org/10.1002/mawe.202300242. DOI: https://doi.org/10.1002/mawe.202300242

[31] A. Amjad, H. Awais, M. S. Z. Abidin & A. A. A. Rahman, “Effect of Al2O3 and MgO nanofiller on the mechanical behaviour of alkaline-treated jute fibre–reinforced epoxy bio-nanocomposite”, Biomass Conversion and Biorefinery 14 (2024) 9749. https://doi.org/10.1007/s13399-022-03032-9. DOI: https://doi.org/10.1007/s13399-022-03032-9

[32] G. Ascensão, F. Faleschini, M. Marchi, M. Segata, J. Van De Sande, H. Rahier, E. Bernardo & Y. Pontikes, “High-temperature behavior of CaO-FeOx-Al2O3-SiO2-rich alkali activated materials”, Applied Sciences 12 (2022) 2572. https://doi.org/10.3390/app12052572. DOI: https://doi.org/10.3390/app12052572

[33] K. Kaur, R. Kaur & H. Kaur, “A systematic review of lignocellulosic biomass for remediation of environmental pollutants”, Applied Surface Science Advances 19 (2024) 100547. https://doi.org/10.1016/j.apsadv.2023.100547. DOI: https://doi.org/10.1016/j.apsadv.2023.100547

[34] M. Santiago Cintrón & D. J. Hinchliffe, “FT-IR examination of the development of secondary cell wall in cotton fibers”, Fibers 3 (2015) 30. https://doi.org/10.3390/fib3010030. DOI: https://doi.org/10.3390/fib3010030

[35] R. Md Salim, J. Asik & M. S. Sarjadi, “Chemical functional groups of extractives, cellulose and lignin extracted from native Leucaena leucocephala bark”, Wood Science and Technology 55 (2021) 295. https://doi.org/10.1007/s00226-020-01258-2. DOI: https://doi.org/10.1007/s00226-020-01258-2

[36] S. Sukhikh, A. Prosekov, S. Ivanova, P. Maslennikov, A. Andreeva, E. Budenkova, E. Kashirskikh, A. Tcibulnikova, E. Zemliakova & I. Samusev, “Identification of metabolites with antibacterial activities by analyzing the FTIR spectra of microalgae”, Life 12 (2022) 1395. https://doi.org/10.3390/life12091395. DOI: https://doi.org/10.3390/life12091395

[37] Y. Huang, L. Wang, Y. Chao, D. S. Nawawi, T. Akiyama, T. Yokoyama & Y. Matsumoto, “Analysis of lignin aromatic structure in wood based on the IR spectrum”, Journal of Wood Chemistry and Technology 32 (2012) 294. https://doi.org/10.1080/02773813.2012.666316. DOI: https://doi.org/10.1080/02773813.2012.666316

[38] P. H. F. Pereira, V. Arantes, B. Pereira, H. L. Ornaghi Jr, D. M. De Oliveira, S. H. Santagneli & M. O. H. Cioffi, “Effect of the chemical treatment sequence on pineapple peel fiber: chemical composition and thermal degradation behavior”, Cellulose 29 (2022) 8587. https://doi.org/10.1007/s10570-022-04806-0. DOI: https://doi.org/10.1007/s10570-022-04806-0

[39] P. Olesik, M. Godzierz, M. Kozio?, J. Ja?a, U. Szeluga & J. Myalski, “Structure and mechanical properties of high-density polyethylene composites reinforced with glassy carbon”, Materials 14 (2021) 4024. https://doi.org/10.3390/ma14144024. DOI: https://doi.org/10.3390/ma14144024

[40] M. I. Uzochukwu, W. U. Eze, P. Garba, M. I. Ugbaja & H. Opara, “Study on the physico-mechanical properties of treated baobab fiber (Adansonia Digitata) nano-filler/epoxy composite”, Multi-scale and Multidisciplinary Modeling, Experiments and Design 3 (2020) 151. https://doi.org/10.1007/s41939-020-00068-0. DOI: https://doi.org/10.1007/s41939-020-00068-0

[41] N. Saba, M. Jawaid, O. Y. Alothman & M. Paridah, “A review on dynamic mechanical properties of natural fibre reinforced polymer composites”, Construction and Building Materials 106 (2016) 149. https://doi.org/10.1016/j.conbuildmat.2015.12.104. DOI: https://doi.org/10.1016/j.conbuildmat.2015.12.075

[42] O. Shakuntala, G. Raghavendra & A. Samir Kumar, “Effect of filler loading on mechanical and tribological properties of wood apple shell reinforced epoxy composite”, Advances in Materials Science and Engineering 2014 (2014) 538651. https://doi.org/10.1155/2014/538651. DOI: https://doi.org/10.1155/2014/538651

[43] J. George, M. Sreekala & S. Thomas, “A review on interface modification and characterization of natural fiber reinforced plastic composites”, Polymer Engineering & Science 41 (2001) 1471. https://doi.org/10.1002/pen.10846. DOI: https://doi.org/10.1002/pen.10846

[44] M. Jawaid & H. A. Khalil, Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review, Carbohydrate Polymers 86 (2011) 1. https://doi.org/10.1016/j.carbpol.2011.04.043. DOI: https://doi.org/10.1016/j.carbpol.2011.04.043

[45] H. A. Rodrı́guez, W. M. Kriven & H. Casanova, “Development of mechanical properties in dental resin composite: Effect of filler size and filler aggregation state”, Materials Science and Engineering: C 101 (2019) 274. https://doi.org/10.1016/j.msec.2019.03.090. DOI: https://doi.org/10.1016/j.msec.2019.03.090

[46] F. Elfakhri, R. Alkahtani, C. Li & J. Khaliq, “Influence of filler characteristics on the performance of dental composites: A comprehensive review”, Ceramics International 48 (2022) 27280. https://doi.org/10.1016/j.ceramint.2022.06.314. DOI: https://doi.org/10.1016/j.ceramint.2022.06.314

[47] W. Brostow & H. E. Hagg Lobland, “Brittleness of materials: implications for composites and a relation to impact strength”, Journal of Materials Science 45 (2010) 242. https://doi.org/10.1007/s10853-009-3926-5. DOI: https://doi.org/10.1007/s10853-009-3926-5

[48] F. Weber, V. Dötschel, P. Steinmann, S. Pfaller & M. Ries, “Evaluating the impact of filler size and filler content on the stiffness, strength, and toughness of polymer nanocomposites using coarse-grained molecular dynamics”, Engineering Fracture Mechanics 307 (2024) 110270. https://doi.org/10.1016/j.engfracmech.2024.110270. DOI: https://doi.org/10.1016/j.engfracmech.2024.110270

[49] A. Pearson, M. Duncan, A. Hammami & H. E. Naguib, “Interfacial adhesion and thermal stability of high-density polyethylene glass fiber composites”, Composites Science and Technology 227 (2022) 109570. https://doi.org/10.1016/j.compscitech.2022.109570. DOI: https://doi.org/10.1016/j.compscitech.2022.109570

[50] K. P. Kaurase & D. Singh, “Influence of filler content on the mechanical, thermal, moisture absorption, and biodegradability properties of bionanocomposite with cellulosic fibers derived from Delonix Regia fruits”, Mechanics of Advanced Composite Structures 11 (2024) 73. https://doi.org/10.22075/macs.2023.30248.1491.

[51] R. Sundarakannan, K. Balamurugan, Y. Jyothi, V. Arumugaprabu, T. Sathish, Z. Mahmoud, E. S. Yousef, D. Basheer & S. Shaik, “Importance of fiber-/nanofiller-based polymer composites in mechanical and erosion performance: A review”, Journal of Nanomaterials 2023 (2023) 3528977. https://doi.org/10.1155/2023/3528977. DOI: https://doi.org/10.1155/2023/3528977

[52] J. L. Thomason & J. L. Rudeiros-Fernández, “A review of the impact performance of natural fiber thermo-plastic composites”, Frontiers in Materials 5 (2018) 60. https://doi.org/10.3389/fmats.2018.00060. DOI: https://doi.org/10.3389/fmats.2018.00060

[53] Y. Sun, Y. Zhao, J. Wu, X. Kai, Z. Zhang, Z. Fang & C. Xia, “Effects of particulate agglomerated degree on deformation behaviors and mechanical properties of in-situ ZrB2 nanoparticles reinforced AA6016 matrix composites by finite element modeling”, Materials Research Express 7 (2020) 036507. https://doi.org/10.1088/2053-1591/ab7b27. DOI: https://doi.org/10.1088/2053-1591/ab7b27

[54] R. L. Oréfice, L. L. Hench & A. B. Brennan, “Effect of particle morphology on the mechanical and thermo-mechanical behavior of polymer composites”, Journal of the Brazilian Society of Mechanical Sciences 23 (2001) 1. https://doi.org/10.1590/S0100-73862001000100001. DOI: https://doi.org/10.1590/S0100-73862001000100001

[55] S. J. Arul, N. M. Basavaraj & J. SP, “Influence of bio fillers on the characteristics of Luffa acutangula fiber reinforced polymer composites and parametric optimization using Taguchi technique”, Scientific Reports 14 (2024) 30730. https://doi.org/10.1038/s41598-024-80316-2. DOI: https://doi.org/10.1038/s41598-024-80316-2

[56] E. Muñoz & J. A. Garcı́a-Manrique, “Water absorption behaviour and its effect on the mechanical properties of flax fibre reinforced bioepoxy composites”, International Journal of Polymer Science 2015 (2015) 390275. https://doi.org/10.1155/2015/390275. DOI: https://doi.org/10.1155/2015/390275

[57] J. Su & J. Zhang, “Comparison of rheological, mechanical, electrical properties of HDPE filled with BaTiO3 with different polar surface tension”, Applied Surface Science 388 (2016) 531. https://doi.org/10.1016/j.apsusc.2015.10.156. DOI: https://doi.org/10.1016/j.apsusc.2015.10.156

[58] E. Kablov & V. Startsev, “The influence of internal stresses on the aging of polymer composite materials: A review”, Mechanics of Composite Materials 57 (2021) 565. https://doi.org/10.1007/s11029-021-09979-6 DOI: https://doi.org/10.1007/s11029-021-09979-6

Published

How to Cite

Issue

Section

Copyright (c) 2025 Daniel S. Sudi, Haruna P. Wante, Ndubuisi Mbada, Isah Baba, Bamidele Boluwatife, Solomon Adeleke

This work is licensed under a Creative Commons Attribution 4.0 International License.